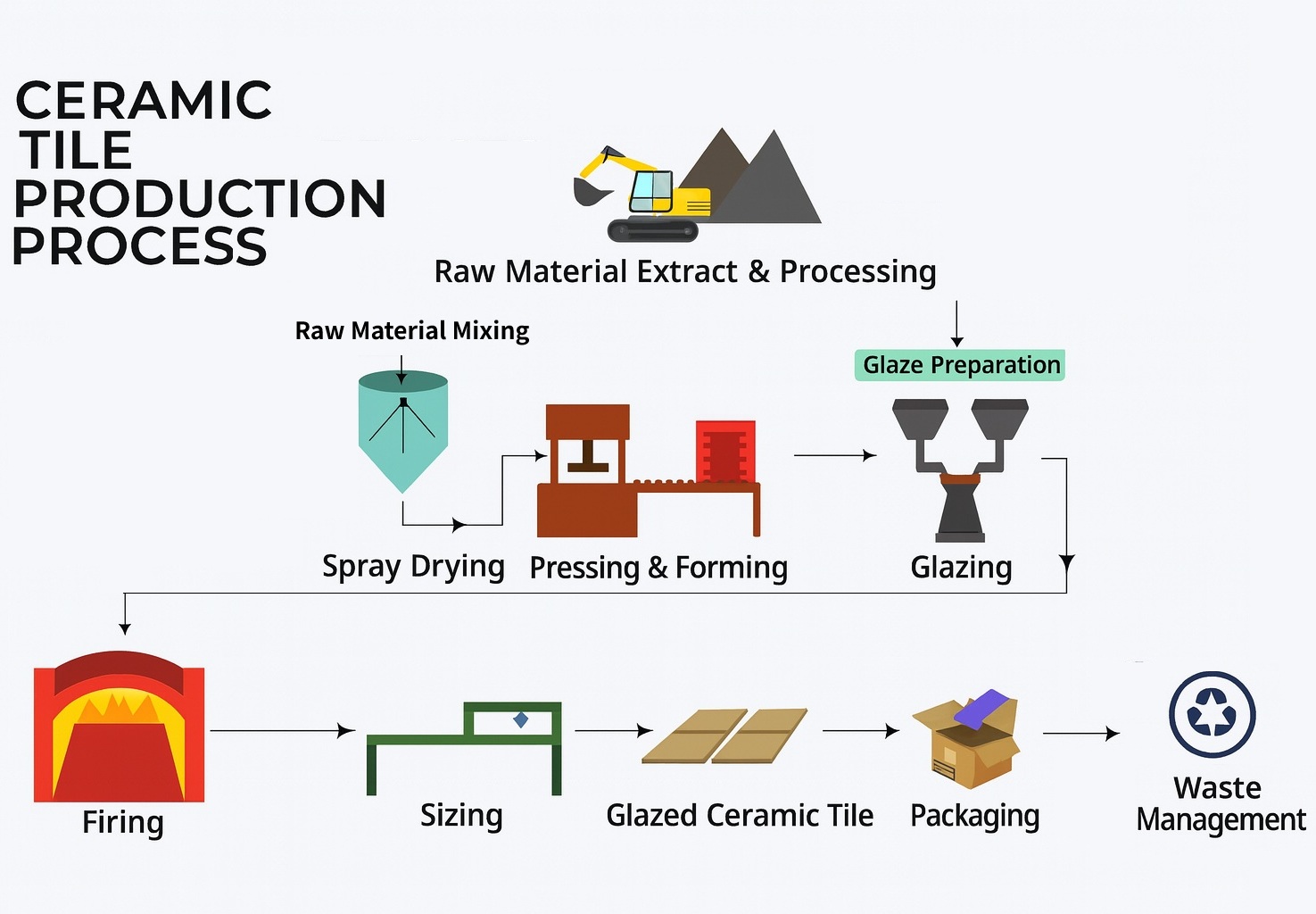

Our ceramic tiles are produced through a carefully controlled manufacturing process that prioritizes quality, efficiency, and environmental responsibility. From raw material preparation to final packaging, each stage is designed to minimize waste, optimize resource use, and deliver durable, high-quality tiles.

Natural raw materials are responsibly sourced, precisely mixed, and processed using efficient technologies such as spray drying and high-pressure pressing. During these stages, excess materials, unfired scraps, and fine particles are recovered and reintroduced into the production cycle. Glaze preparation and application are managed through controlled systems that allow the reuse of excess glaze and process water, reducing material loss and water consumption.

Energy-efficient kilns are used during firing to achieve optimal performance with reduced energy use. After firing, tiles are accurately sized, inspected, and packaged using recyclable materials. Throughout the entire process, waste is carefully managed and recycled wherever possible, reflecting our commitment to green production and sustainable manufacturing practices.